How to Make a Teapot in 1 Class Period

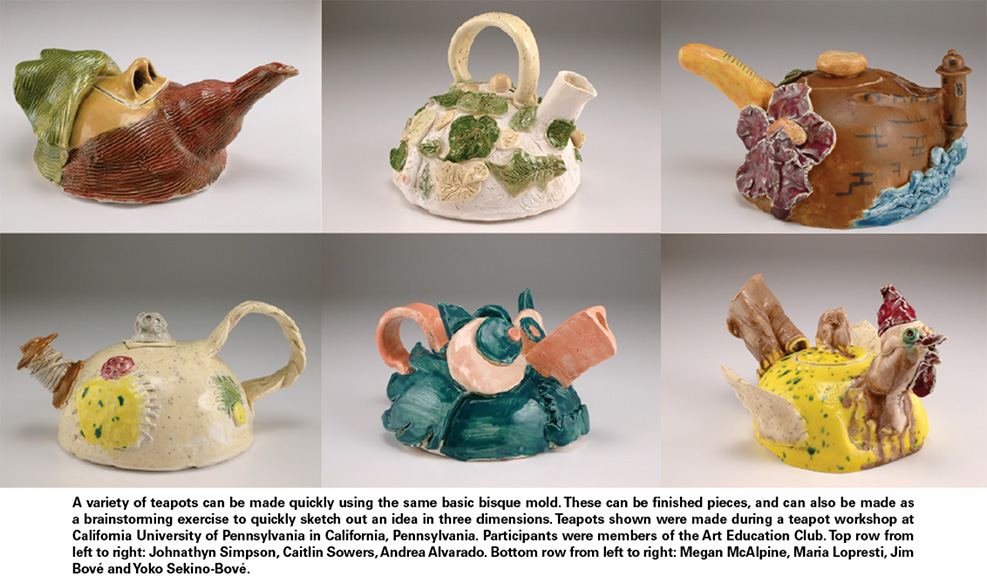

Learning how to make a teapot is a challenge and a milestone for potters. There are so many components to consider: the teapot spout, the handle, the knob. But the same reason learning how to make a teapot is a challenge, is why it is also a lot of fun. Trying to teach students how to make a teapot in one class period might sound impossible. But Yoko Sekino Bove has found a way and she shares this great ceramic lesson plan today!

In this post, an excerpt from the pages of Pottery Making Illustrated, Yoko Sekino Bove shares the lesson plan for her 30-Minute Teapot . The beauty of this ceramic lesson plan for teachers is that students can learn how to make a teapot in one class period. If you’re not a teacher, it’s a fun little project to experiment with if you’re needing a break from your usual routine.

Making a teapot is considered a milestone for many people learning pottery, and it’s often presented as an intellectual challenge. While some get intimidated and struggle to complete their first one, making a teapot becomes easier and more fun the more you make. Teapots are an exercise in designing a three-dimensional structure as well as studying function, proportion, and surface decoration.

This 30-minute teapot ceramic lesson plan offers an opportunity for instructors to talk about teapot mechanics, while allowing students to experiment with design elements. It seems easier for my students to learn how to make their first teapot with handbuilding techniques because they have more control over the forms and sizes.

I consider this ceramic lesson plan a good exercise before proceeding to more complicated, time-intensive projects. Construction of this soft-slab project is finished in one class session without coming back to trim or clean. The teapots will be ready for bisque firing a day or two after construction, so it’s entirely possible for students to complete the whole project within a week.

Ceramic Lesson Plan: How to Make a Teapot in 10 Easy Steps

Step 1: Gather Tools and Materials

To teach how to make a teapot, you’ll need clay; a fettling knife; a rolling pin or a slab roller; a dry sponge; a rubber or metal rib; a scoring tool; chopsticks; as well as paintbrushes, stamps, and other decorating tools. To form the slab teapot, you’ll need a bisqued or plaster dome-shaped hump mold (in order to make this project fit into a class period, the mold should be absorbent) and a container to put the mold on. Lastly, it is helpful to have a piece of cardboard to support the bottom of the teapot on to make moving it around easier.

Step 2: Roll Out a Slab

Make the slab big enough for the body, bottom, handle, and spout of your teapot, depending on the size of mold. Since the teapot will be built using soft slabs, the slab should be approximately 1/4 inch thick. Save the leftover clay for a knob, supports for propping up the handle and spout if needed, and decorations.

Step 3: Create the Body

Cut out a section of the slab roughly large enough to cover your mold. Drape the slab over the elevated mold (figure 1). To make the flat sheet fit to the mold, either tuck and fold the excess clay or cut darts from the edges and reattach the edges, adding a thin coil to reinforce and patch up the join. Cut excess off the bottom using the rim of the mold as a guide (figure 2). When pressing the clay against the mold to make it conform to the shape, do not push the clay down with your fingers; use a dry sponge, a rib, or the palm of your hand to pat gently instead. This helps keep the slab thickness even.

Step 4: Make the Spout

With brush handle or chopstick, roll up a thinner sheet of clay into a tube. Rock the spout gently on a flat surface to make it look even and round. Make a few spouts to choose from.

Step 5: Knob & Lid

The knob can be any style you choose (figure 3). Use a fettling knife to make the lid cut and make the cut on an angle so that the lid has support and sits on the body. Cutting the lid on an angle like this removes the need for a gallery to be added to the body. The lid can be an organic shape to indicate the direction, or you can put little matching marks on the lid and body to line it up. After removing the lid, drape a little strip or two of newspaper on the body to prevent the lid sticking to the body (see image 5).

Step 6: Attach the Spout

Hold the spout up to the body, and mark an outline around it where it will attach. Set the spout aside, then make several small strainer holes within the outlined area. Small holes maintain the wall strength better than one big hole, minimizing the chance that the form could warp or crack. Score the marked areas on the body and the spout before attaching. Push the spout firmly onto the body and make sure there is a good seal. You don’t need to use slip or water to attach it, the clay gets too soggy and starts collapsing. Later, you will have a chance to insert a support under the spout if the angle is a concern (figure 4).

Step 7: Make & Attach Handle

It’s safer to attach the handle while the body is supported by a mold if possible, to minimize distortion. If the handle is a tube structure, make sure there is a hole to release the air. Once the handle is added, it’s safe to remove the body from the mold.

Step 8: Attach the Bottom

Place the bottom on cardboard, score around the edge where the body sits, and add slip to the scored edge. Score the bottom edge of the body, remove it from the mold and attach it to the bottom (figure 5). Clean up the seams after joining (figure 6).

Step 9: Finishing Details

Place supports under the spout and handle if needed. Place a piece of paper in between the support and the handle or spout so that it does not stick. Make a small air hole on the lid to allow liquids to pour more smoothly. Attach a stopper on the bottom of the lid to prevent the lid from falling off when the teapot is tilted.

Step 10: Dry Slowly

Sometimes the lid will not fit if it was separated during the drying process due to warping. It is safer to let the whole teapot dry and go through the bisque firing as one piece.

Yoko Sekino-Bove is an artist and instructor living in Washington, Pennsylvania. In addition to contributing to PMI, she has written for Ceramics Monthly magazine. To see more of her work, visit www.yokosekinobove.com.