It’s Monday, and if you are one who notices patterns, you may have noticed that every other Monday lately, we have been rolling out a new free download for our subscribers. And guess what! Today is one of those every other Mondays!

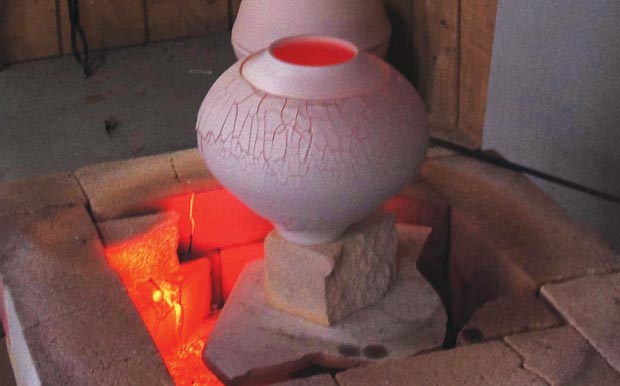

In today’s post, I am presenting an excerpt from it, which explains how Satori Yamaoka combines both oxidation and slight reduction to create amazing oil-spot surfaces in his innovative electric and propane kiln. – Jennifer Poellot Harnetty, editor

Electric and Propane Combination Firing

One of the more interesting aspects of Satori Yamaoka’s firing method involves combining electric and propane, a method he has used for about 40 years. He has three electric kilns that go to Cone 9, all of which are designed to allow a small amount of propane to be used at a certain point during the firing cycle.

Using a computer that he has programmed to increase the rate of heat evenly with straight oxidation, electricity is used as the only heat source in the beginning of the firing. At around Cone 08, he introduces a small amount of propane to slightly reduce the atmosphere. This continues to Cone 9, which usually takes 24 hours.

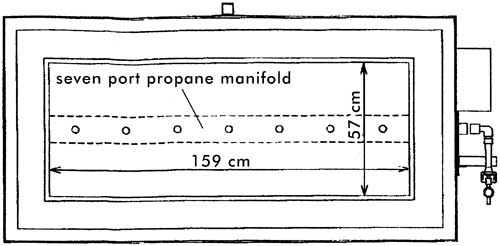

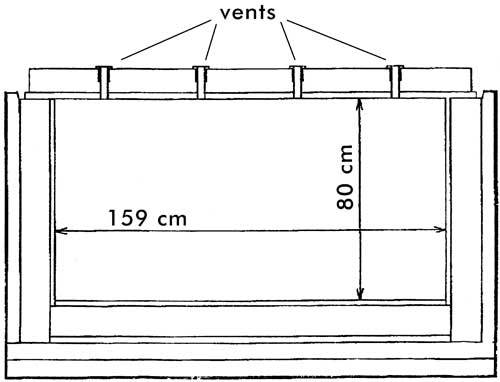

This type of firing has evolved from considerations of cost and the colors Yamaoka wants in the finished ware. The kilns are large, custom-made, rectangular, top-loading electric kilns. The interior dimensions are 159 X 57 X 80 centimeters, (63 X 22 X 32 inches), with about 23 centimeters (9 inches) of brick and fiber insulation. Electric elements are anchored to the fiber hot-face. There are eight exit ports about 3 centimeters (1 1/4 inches) in diameter on the sides, front and back (two on each side). A ratchet-and-cable system lifts and holds the lid open.

Yamaoka fires about 10 electric/propane firings per month. The exact firing schedule varies a lot, but the first part is always electric guided by computer. There are always variables that affect the latter part of the schedule: stacking, which glazes are included, whether saggars are used, etc. So when the propane is introduced, things may change from firing to firing.

Kiln Diagrams

Glaze Recipes

| Kujaku (Peacock) Glaze, Type 1 | Cone 9, reduction |

| Glaze Material | |

| Barium Carbonate | 11% |

| Bone Ash | 2% |

| Magnesium Carbonate | 3% |

| Strontium Carbonate | 6% |

| Whiting | 8% |

| Potash Feldspar | 42% |

| Kaolin | 8% |

| Silica (Flint) | 20% |

| Total | 100% |

| Add: | |

| Copper Oxide | 4% |

| Tin Oxide | 3% |

| Silicon Carbide | 4% |

| Shinsha Glaze, Layer 1 | Cone 9, reduction |

| Glaze Material | |

| Barium Carbonate | 18% |

| Whiting | 7% |

| Potash Feldspar | 38% |

| Kaolin | 12% |

| Silica (Flint) | 25% |

| Total | 100% |

| Add: | |

| Red Iron Oxide | 1% |

Satori combines several glazes to get the Peacock affect shown above. Because this glazing process involves several layers, thickness will affect the result.